600N Auto Repair Electric Wrench

600N Auto Repair Electric Wrench

In extreme working conditions such as heavy truck maintenance, rail construction, and power equipment assembly, traditional hydraulic tools have fatal defects such as bulkiness and short battery life. The industrial-grade 600N brushless wrench, with military-grade materials and fifth-generation brushless technology, can achieve single-handed operation and output 600N·m nuclear-grade torque, redefining the performance benchmark of industrial power tools.

Five heavy-duty core technologies

Military powertrain system

Industrial-grade brushless motor: breakthrough 600N·m output torque (equivalent to the combined force of 10 adults)

Double forged steel impact module: 6300 times/minute high-frequency impact, easy to remove rusted bolts

Aviation-grade heat dissipation architecture: 72 hours of continuous operation, core temperature stabilized within 85℃

Ultra-durable transmission structure

Tungsten steel shaft + high aluminum head: passed MIL-STD-461F electromagnetic interference test

Self-lubricating bearing system: 300,000 impact tests without attenuation

IP67 protection level: 3-meter drop resistance/oil erosion resistance/acid and alkali corrosion resistance

Actual performance breakthrough

Heavy truck tire removal: Traditional solution: 15 minutes/wheel | This tool: 22 seconds violent removal

Rail bolt maintenance: M36 bolt removal efficiency increased by 400%

Substation equipment maintenance: 60mm diameter anchor bolts are loosened in 15 seconds

Records of attacking four major industrial scenarios

1. Revolutionary in the field of auto repair

● Easily handle American truck wheel hub screws (standard torque 550-750N·m)

● Equipped with 22mm industrial socket, gnaw-type anti-slip pattern design

● Intelligent mode automatically identifies bolt specifications to prevent over-torque damage

2. Rail transit special forces

● Batch maintenance of rail fishplate bolts

● Disassembly and assembly of railway turnout adjustment devices

● Anti-electromagnetic interference design, safe operation under the contact network

3. Guardian of power engineering

● Tightening of transformer installation anchor bolts

● Removal of M56 high-strength bolts of tower angle steel

● Maintenance of GIS equipment in substations

4. Heavy machinery equipment technician

● Maintenance of port crane slewing bearings

● Replacement of shield machine cutter head bolts

● Flange connection of wind turbine tower

Intelligent control system analysis

Industrial human-computer interaction

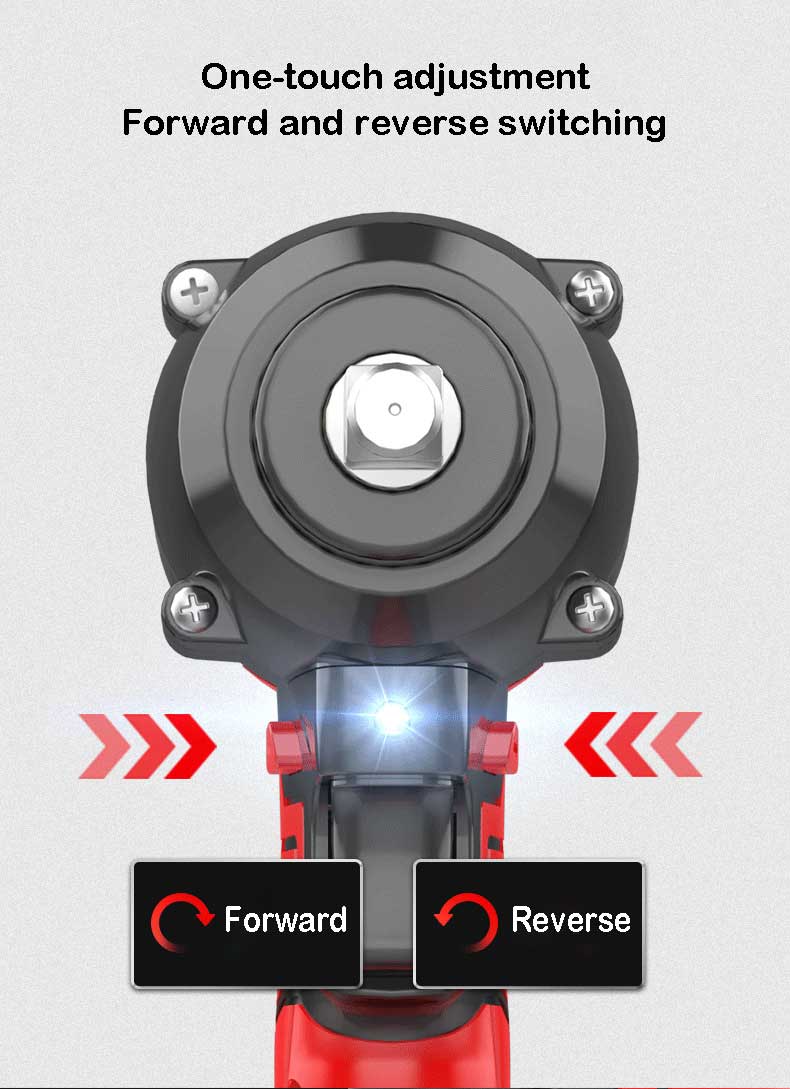

◆ Three-mode intelligent switching:

Precision mode (50-200N·m)

Standard mode (200-400N·m)

Violence mode (400-600N·m)

◆ Dynamic torque compensation technology:

Real-time perception of bolt status, automatic adjustment of output strategy

◆ Five-protection safety system:

Overload power off/high-temperature warning/low-temperature protection/voltage monitoring/waterproof trigger

Super endurance solution

21700 industrial battery pack:

● 15 automotive-grade power batteries

● Support -40℃ extreme cold start

● 120-minute full-blood fast charge

Intelligent battery management system:

● Independent monitoring of battery cells, temperature difference ≤1.5℃

● Charge and discharge control 2000 times capacity rate>85%

● Accurate display of percentage (1% accuracy)

Humanized engineering design

Military protection system:

● Three-level telescopic structure (handle/head/battery compartment)

● 60° anti-roll cage design

| Product | 600N Industrial Auto Repair Wrench |

| Voltage | 21V |

| Torque | 600N |

| Maximum power | 900w |

| No-load speed | 0~2100r/min |

| Speed regulation | Continuously Variable Speed |

| Battery power | 4~7.5Ah |

| Chuck size | 13mm |